With the acceleration of electrification, battery thermal management (BTMS) has become a core factor determining the safety, performance, and lifespan of electric vehicles. Maintaining the power battery at its optimal operating temperature of approximately 20–45°C significantly improves energy efficiency and reduces the risk of thermal runaway. Furthermore, the source of battery temperature is simply due to the battery’s internal resistance and high external temperatures.

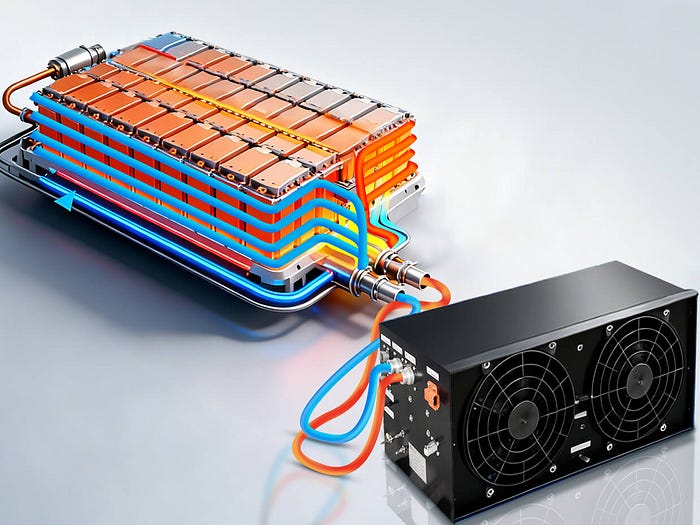

Battery pack thermal management consists of three core components: cooling circuit, control unit, and sensors. Based on the heat dissipation method, it can be divided into passive and active methods. Passive systems have a simple structure and are only suitable for small-capacity applications. Active systems achieve more precise temperature control through methods such as fans or coolants. Currently, the mainstream solution for heavy-duty electric vehicles is liquid cooling, which can achieve more uniform temperature distribution, suppress thermal peaks, and extend battery life.

Currently, cutting-edge technologies mainly include nanofluids, phase change materials (PCMs), and immersion cooling. These technologies all have their own potential for the future, but each still has its own unresolved shortcomings. TKT is currently a liquid-cooled BTMS solution provider for Fortune 500 companies BYD and Tata Motors. We have our own factories in China and India. Our products are suitable for the thermal management of various heavy-duty commercial vehicles.

If you are responsible for the design of a new vehicle, you should focus on the temperature uniformity, control strategies, and leak prevention of the liquid cooling system, while also assessing maintenance costs. For complete technical details and case studies, please click to read the original article.