All Series Specification Table:

|

Model |

TKT-160E |

TKT-260E |

TKT-420E |

|

|

|

|

|

|

Cooling |

16 KW |

26 KW |

42 KW |

|

Heating |

Heating Pump is optional |

|

Control way |

Digital control panel + CAN Control(optional) |

|

Application |

6-7m EV Bus |

9-10m EV Bus |

12m EV Bus |

|

Refrigerant |

R134A |

R407C |

|

Compressor Voltage/Power Supply |

DC250-350V |

DC450-750V |

|

Control Voltage/Power Supply |

DC24V/8A |

DC24V/10A |

|

Compressor |

Electric compressor(42 cc/r) |

Japan SANYO Brand Vortex Compressor(74.4 cc/r) |

|

Condenser |

Model |

Copper Tube and Aluminum Fin Structure |

|

Fan Air Volume |

3600 m³/h(2Fans)(3 fans is available, based on clients need) |

7200 m³/h(4Fans) |

9000 m³/h(6Fans) |

|

Evaporator |

Model |

Copper Tube and Aluminum Fin Structure |

|

Blowers Air Volume |

7200 m³/h(4Blowers) |

10800 m³/h(6Blowers) |

14400 m³/h(9Blowers) |

|

Dimension |

2700*1630*195mm |

2700*1830*250mm |

3200*1830*250mm |

| |

Weight |

185KG |

260KG |

280KG |

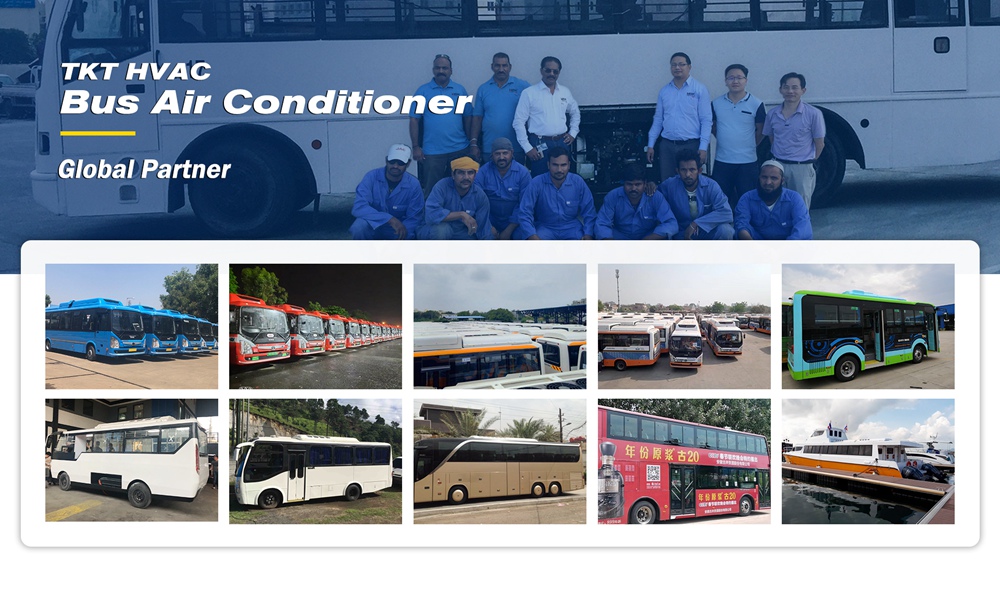

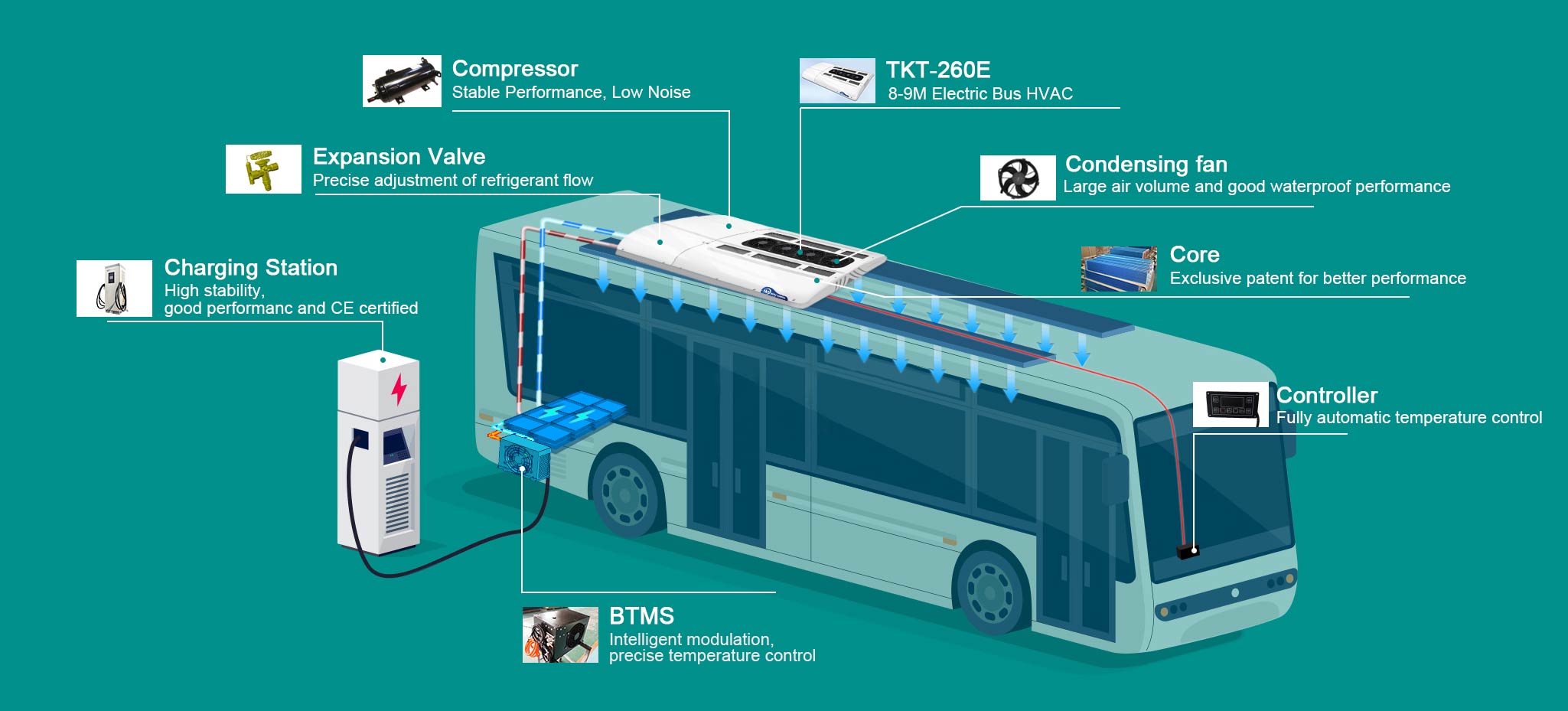

As a leading technology manufacturer of bus air conditioners, truck air conditioners, and RV air conditioners in China, TKT never stops innovating new technologies.

We are a professional bus air conditioner manufacturer. Our air conditioning systems are widely used in carrier bus air conditioners, minibus air conditioners, shuttle bus air conditioners, electric bus air conditioners, bus HVAC systems, etc.

TKT bus air conditioner types are suitable for bus rooftop air conditioners. Having confidence in your products is the first step to the world market. Choosing a quality supplier to work with will make your business twice as successful. We can offer you the best TKT bus air conditioner prices.

.jpg) Choice of materials:

Choice of materials:

The materials used in all TKT products are internationally recognized brands. We select suppliers from all over the world and work with the world's top brands such as Bitzer, Bock, Danfoss, Sanden, Valeo, Alco, and Goodyear. insisting on using copper tubes and aluminum plates will make the products more durable and extend their lifespan.

Safety and stability:

Safety and stability:

Our electric vehicle systems are designed for both safety and stability. Despite being the largest, our 12-meter electric vehicle model measures no more than 3.2 meters in width. This compact design not only reduces the vehicle's overall weight but also enhances its safety profile. It further contributes to increased capacity and mileage for the electric vehicle.

To ensure safety, we've implemented a robust safety protection mechanism. This includes the use of high-quality electrical components and additional fuses to withstand high voltage. Additionally, our systems feature various protective mechanisms, such as high-voltage and low-voltage protection, to safeguard the AC system effectively.

Exclusive design:

Exclusive design:

Our condenser coil structure boasts an exclusive, patented design that maximizes heat release area while minimizing material usage. This design is renowned as the epitome of heat exchange efficiency in China.

We use high-quality inner-threaded copper tubes and hydrophilic aluminum fins to construct the condenser and evaporator coils. These materials offer superior corrosion resistance, making them ideal for coastal regions, and have a lifespan of over 10 years, surpassing parallel-flow coils made of pure aluminum.

To ensure reliable and exceptional cooling performance, we employ the finest compressor available in the Chinese market, a proven choice with an 8-year track record.

Our advanced CAN control, coupled with an integrated digital control panel, results in a significantly lower failure rate compared to PLC control systems.

So, why not choose TKT?

Brand Partnership Strength:

In the international market, TKT is the OEM of TATA Motors, TATA Marcopolo Motors, Daewoo, etc., and exports to sales and service centers in 85 countries. After 24 years of experience, we are getting more and more comfortable with production to meet the demanding needs.

.jpg) Design Capability:

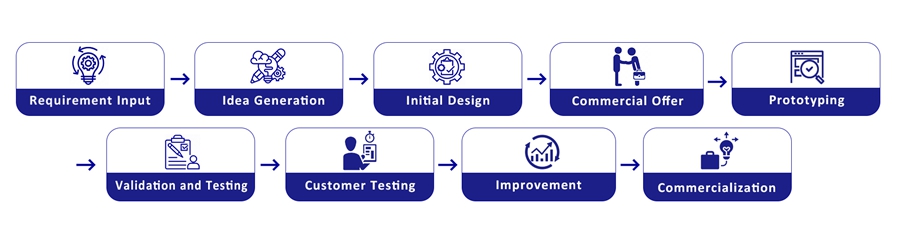

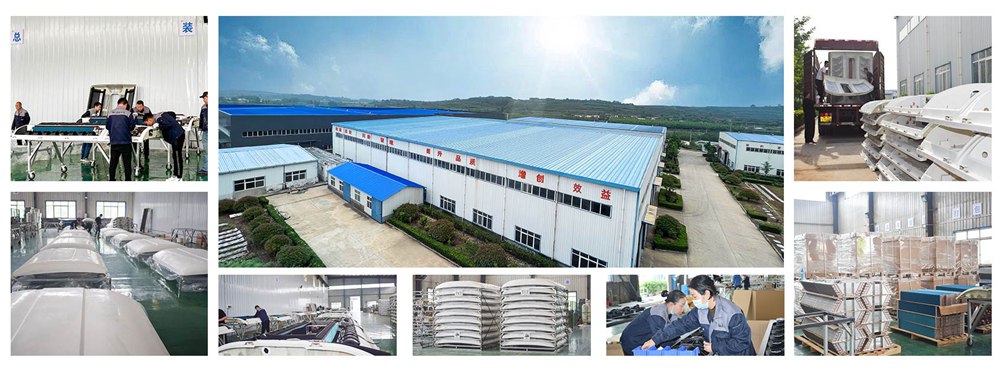

Design Capability:

As the world's leading manufacturer of refrigeration equipment, TKT has a team of 135 engineers, including design engineers, structural engineers, electrical engineers, test engineers, EMI/EMC engineers and after-sales engineers, with complete design, development, testing and certification capabilities for refrigeration equipment and components. The patented coil structure design will be more economical. The attention to detail has led to increasingly higher quality products.

What is service?

What is service?

Insisting on making the best products and reducing after-sales is the best service. Our bus air conditioning system has the advantages of energy saving, environmental protection, low noise, long life and high reliability. And we have successfully solved the difficulties of high current consumption of brushed motor fan, high starting current, short service life, electric spark generation as well as low efficiency, high noise and difficult maintenance. Also TKT has an experienced after-sales team in China and around the world, providing local service in 85 countries and extensive after-sales technical support for all OEMs.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)