Product CaTEGORY

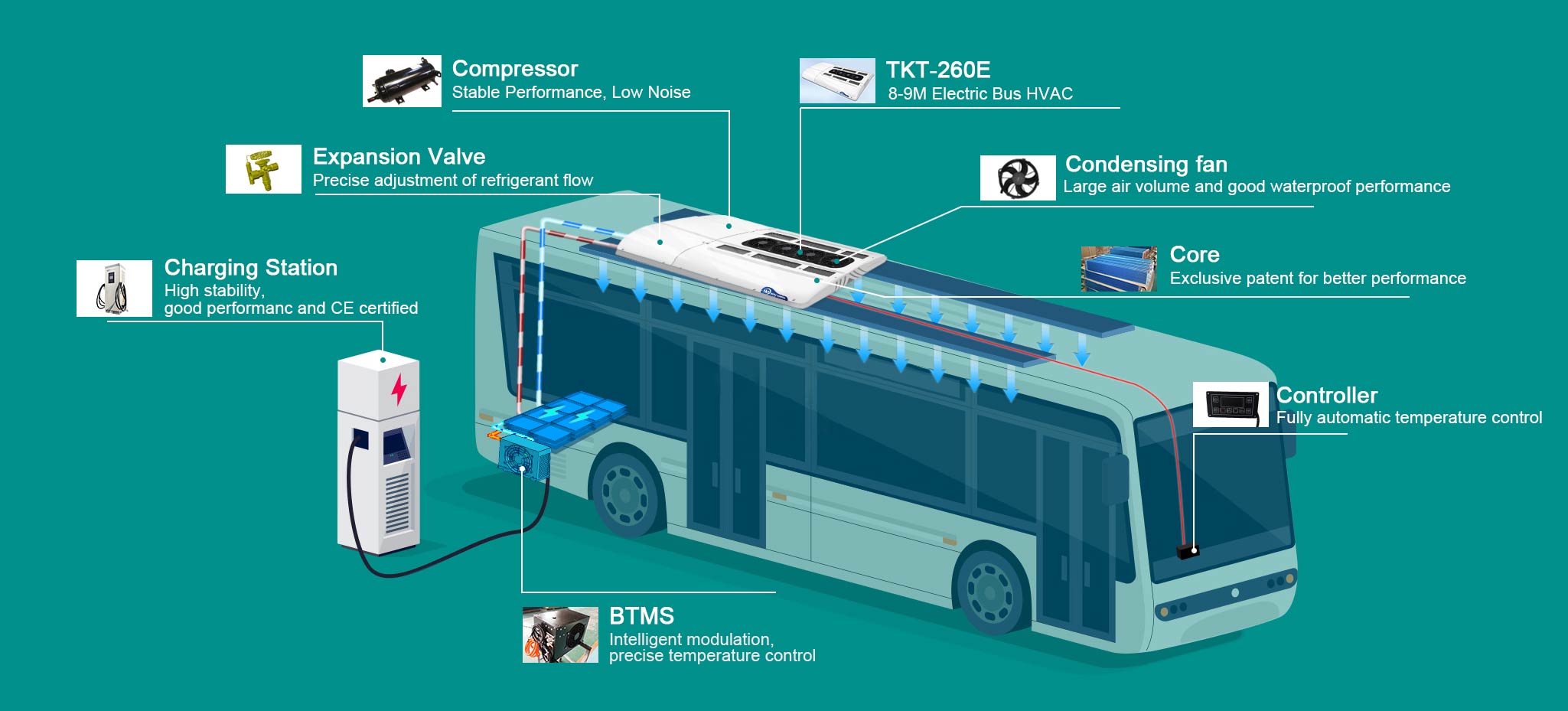

TKT battery thermal management system can be used in electric buses. In order to ensure safety and prolong the service life of electric bus batteries, the power system and energy system must operate under optimal thermal conditions (15-35℃). If the battery overheats, the electrochemical aging process will begin. Performance will also be greatly reduced if the battery is operated at temperatures below 20°C.

TKT battery thermal management system can be used in electric buses. In order to ensure safety and prolong the service life of electric bus batteries, the power system and energy system must operate under optimal thermal conditions (15-35℃). If the battery overheats, the electrochemical aging process will begin. Performance will also be greatly reduced if the battery is operated at temperatures below 20°C.

(1).jpg)

Condenser coil, condenser fan, water tank, water pump, heat exchanger, electric compressor, control panel, CAN module, expansion valve, etc.

The condenser system cools down the coolant and the water pump will run the coolant through the BCS and the battery structure system to release the heat generated by the battery pack.

1. Patented design for high cooling/heating effect with low weight.

2. CAN control to avoid damage to the battery pack by incorrect operation

3. Precise temperature control (0.5 degrees Celsius)

4. Use of IP67 electrical components, such as electric compressor, water pump, connectors, etc.

5. Quality and performance are recognized worldwide.

6. Reliable support and service.

Battery thermal management systems are critical for optimizing performance, extending battery life, ensuring safety, optimizing charging cycles, adapting to different environments, and promoting environmental sustainability. While advances in battery technology have brought tremendous benefits, battery thermal management remains a fundamental aspect that cannot be ignored. Using our BTMS not only enhances the user experience but also protects against potential hazards and maximizes the overall potential of battery-powered equipment.

We offer you more than just our products. We are there for you every step of the way. Our technicians advise you from the very beginning and integrate our solutions perfectly into your existing systems. We also welcome all good OEMs to discuss technology and developments with us. Based on the market demand for electric commercial vehicles, TKT began to develop and design a battery thermal management system (Battery Thermal Management System, BTMS) in 2012. To meet these challenges, TKT has developed a series of products to solve these problems. For each component to operate under optimized thermal conditions, resulting in longer life and higher efficiency.

OEM/ODM Process

TKT has a team of 135 engineers including design engineers, structural engineers, electrical engineers, test engineers, EMI/EMC engineers and after-sales engineers with complete design, development, testing and certification capabilities for refrigeration equipment and components. TKT BTMS is now available for electric Bus, truck, off-highway, boat and other commercial vehicles. We also provide design and technical support to the world's leading vehicle manufacturers.

TKT not only manufactures BTMS systems for electric vehicles, but we also produce electric bus air-conditioning systems, truck refrigeration units, and electric vehicle charging posts. If you are interested in working with TKT, please feel free to contact us.