Battery Thermal Management System Overview

As technology advances and devices become more compact, efficient, and powerful, managing heat has grown increasingly critical. Among these innovations, batteries play a vital role. They store energy, supply power, and enable mobility across numerous industries—from electric vehicles (EVs), portable electronics, grid storage systems, medical equipment, aerospace applications, and beyond.

However, their performance can suffer due to temperature fluctuations, which may lead to reduced lifespan, efficiency losses, safety hazards, and even catastrophic failures. Therefore, regulating battery temperatures within optimal ranges becomes essential, giving rise to the need for specialized solutions known as battery thermal management systems (BTMS).

In this article, we will explore what comprises such systems, why controlling battery temperature matters so much, various types of cooling techniques employed, and potential future trends shaping this field.

.jpg)

Why Is Battery Temperature Crucial?

Temperature affects several aspects related to battery operation, including capacity degradation, electrochemical reactions, self-discharge rate, internal resistance, and aging mechanisms. For instance, excessive heating can accelerate chemical reaction rates inside the cell, causing irreversible damage over time, reducing overall battery life expectancy, and posing fire risks. On the contrary, extremely low temperatures hinder ion movement, leading to diminished power output and longer charging times. As a result, maintaining ideal operating conditions enhances safety, extends service life, improves efficiencies, and maximizes reliability.

Factors Affecting Battery Temperature

Several factors influence battery temperature, such as ambient environment, charge/discharge cycles, load demands, insulation materials, and cooling methods used. Designers must consider each aspect carefully during development stages since any mismanagement could compromise performance and endurance. To understand how these elements interact, let us examine them individually below:

- Ambient Environment: Surrounding air temperature plays a significant role in determining battery heat generation. High external temperatures exacerbate heat dissipation challenges, whereas colder environments necessitate additional heating measures to maintain desired operational levels.

- Charge/Discharge Cycles: Rapid charging or discharging processes generate considerable amounts of waste heat, elevating battery temperatures significantly. Prolonged exposure to extreme states hastens degradation, thereby shortening useful lifetime.

- Load Demands: Power-intensive operations consume substantial current flow, increasing heat production. Thus, identifying peak usage periods enables developers to incorporate appropriate thermal mitigation strategies effectively.

- Insulation Materials: Selection of proper insulators around cells impacts thermal conductivity, influencing heat transfer between adjacent components. Utilizing advanced insulation materials reduces unwanted heat transmission while preserving required isolation properties.

- Cooling Methods: Implementing effective cooling techniques manages excess heat efficiently, safeguarding longevity and improving overall system stability. This leads us directly into discussing different

types of BTMS solutions available today.

What Exactly Is a Battery Thermal Management System (BTMS)?

In essence, a BTMS constitutes a series of interconnected hardware and software components designed explicitly to monitor, control, and optimize battery temperature across varying environmental conditions. By employing intelligent algorithms, sensors, actuators, and specialized cooling mechanisms, BTMS ensures uniform distribution of temperature throughout the entire battery pack, minimizing hotspots and cold spots formation, thus preventing premature failure modes. Furthermore, integrating predictive analytics allows engineers to anticipate potential issues beforehand, enabling preventative maintenance actions and extending product lifetimes.

Types of BTMS Solutions

Two primary categories define most existing BTMS architectures – passive and active cooling techniques. Each approach offers distinct advantages depending on application requirements, size constraints, cost limitations, complexity preferences, and design goals. Let us delve deeper into understanding each methodology:

Passive Cooling Methods

Passive cooling relies solely on natural convection, conduction, and radiation principles without relying on external power sources or moving parts. These inherently simple designs prioritize minimalistic approaches, making them attractive options for budget-conscious projects seeking reliable yet affordable solutions. Here are some common examples:

- Natural Convection: Leveraging differences in fluid density caused by temperature gradients creates buoyancy forces driving warm air away from the source and drawing cooler air toward it. Installing ventilation slots promotes circulation, facilitating heat expulsion passively.

- Conduction: Directly contacting solid surfaces transmits heat through molecular collisions, allowing rapid exchange between objects sharing physical boundaries. Appropriately positioning thermally conductive materials near batteries expedites heat dispersion naturally.

- Radiation: Emitting electromagnetic waves carrying energy across empty spaces contributes marginally to total heat loss but remains significant in certain scenarios. Integrating reflective coatings limits radiated emissions, lowering surface temperatures indirectly.

Active Cooling Techniques

Active cooling employs mechanical assistance to augment heat removal capabilities proactively. Such methods typically involve forced convection via fans or blowers, liquid cooling circuits, phase change materials (PCMs), Peltier effect modules, or combinations thereof. Although requiring additional resources, these sophisticated setups excel in demanding situations where higher performance thresholds must be maintained consistently. Below are popular active cooling implementations worth noting:

- Forced Convection: Mechanically propelled fluids (air or liquids) transport heat away swiftly, capitalizing on increased mass flow rates induced by fan blades spinning at controlled speeds. Adjusting fan curves based on real-time feedback maintains optimal thermal profiles dynamically.

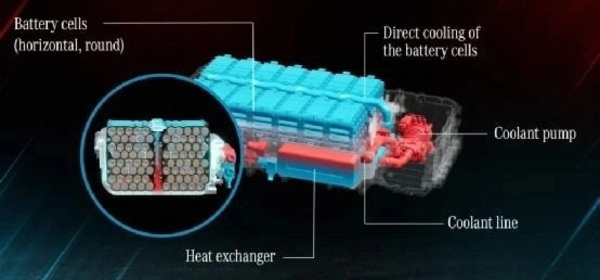

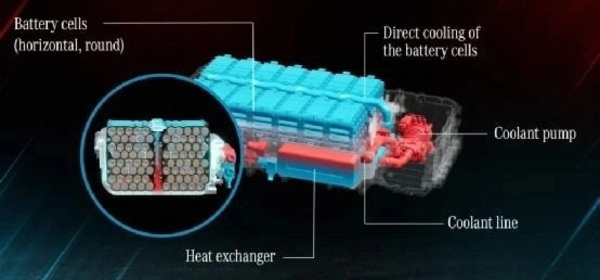

- Liquid Cooling Circuits: Fluid loops filled with dielectric coolants absorb heat from embedded plates attached to battery casings, subsequently releasing absorbed energy to remote heat exchangers through continuous recirculation.

- Phase Change Materials (PCMs): Latent heat storage capability characterizes PCMs, absorbing large quantities of thermal energy during melting transitions and releasing stored latent heat during solidification. Strategically placing PCM containers around critical zones absorbs sudden spikes in localized temperatures, tempering extremities gracefully.

- Peltier Effect Modules: Also called thermoelectric coolers, Peltier modules utilize semiconductor junctions subjected to electrical voltage differentials to pump heat unilaterally against imposed gradients. Despite relatively low efficiencies compared to traditional refrigeration technologies, their compact form factor, silent operation, and ease of integration render them appealing choices for niche markets.

Having explored the diverse range of BTMS solutions currently available, let us now turn our attention towards appreciating their benefits and widespread adoption across multiple domains.

.jpg)

Advantages & Applications of BTMS

By stabilizing battery temperatures within prescribed bounds, BTMS unlocks numerous advantageous outcomes concerning efficiency enhancements, extended durability, heightened safety, and versatile utilization.

Electric Vehicles

The transportation industry stands poised to undergo transformative changes driven primarily by EV adoption trends. With stringent emission norms looming globally, automakers look keenly towards incorporating cutting-edge BTMS designs to ensure superior range, quicker refueling times, improved passenger comfort, and enhanced crashworthiness characteristics. Specific use cases include:

- Regenerative Braking Heat Recovery: Harvesting kinetic energy generated during deceleration events converts wasted motion back into usable electricity, prolonging drive distances while simultaneously alleviating brake fade concerns associated with frequent stopping instances.

- Predictive Climate Control: Anticipatory cabin conditioning preemptively adjusts interior temperatures according to occupant habits, weather forecasts, GPS data, and traffic patterns, conserving valuable battery reserves en route.

- Fast Charging Support: Accelerated DC charging sessions demand judicious thermal oversight to avoid detrimental side effects arising from excessive heat accumulation during sustained high-power input phases.

TKT BTMS products are suitable for battery energy storage management systems such as pure electric buses, hybrid buses, extended range hybrid light trucks, hybrid heavy trucks, pure electric engineering vehicles, pure electric excavators, pure electric forklifts, etc.

By controlling the temperature, the power battery can work in the normal temperature range in both high temperature areas and cold areas, thereby prolonging the service life of the power battery and improving the safety of the power battery.

.jpg)

.jpg)