Product CaTEGORY

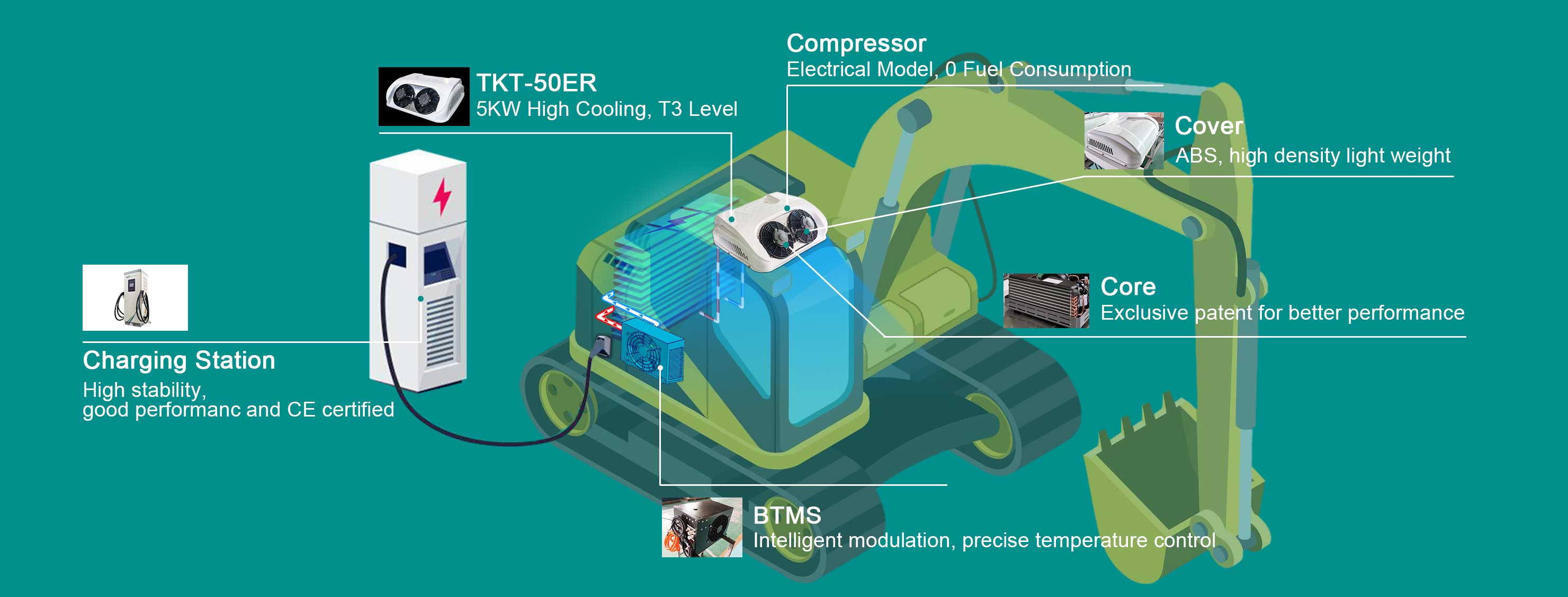

TKT Battery Thermal Management can be used in EV Heavy Equipment. Cities need construction sites to cope with the constant changes being made to meet the latest standards. See construction vehicles are a common and almost daily part of urban life. Construction machinery such as excavators are indispensable in order to complete reconstruction work as quickly as possible. They transport heavy loads on a daily basis and therefore work harder than ordinary vehicles. However, a large amount of fuel is consumed, which increases CO2 emissions. With this in mind, purely electric vehicles are the best way to protect the climate and save costs, while also advancing the modernization of cities.

Cities need construction sites to cope with the constant changes being made to meet the latest standards. See construction vehicles are a common and almost daily part of urban life. Construction machinery such as excavators are indispensable in order to complete reconstruction work as quickly as possible. They transport heavy loads on a daily basis and therefore work harder than ordinary vehicles. However, a large amount of fuel is consumed, which increases CO2 emissions. With this in mind, purely electric vehicles are the best way to protect the climate and save costs, while also advancing the modernisation of cities.

(1).jpg)

Condenser coil, condenser fan, water tank, water pump, heat exchanger, electric compressor, control panel, CAN module, expansion valve, etc.

The condenser system cools down the coolant and the water pump will run the coolant through the BCS and the battery structure system to release the heat generated by the battery pack.

1. Patented design for high cooling/heating effect with low weight.

2. CAN control to avoid damage to the battery pack by incorrect operation

3. Precise temperature control (0.5 degrees Celsius)

4. Use of IP67 electrical components, such as electric compressor, water pump, connectors, etc.

5. Quality and performance are recognized worldwide.

6. Reliable support and service.

We offer you more than just our products. We are there for you every step of the way. Our technicians advise you from the very beginning and integrate our solutions perfectly into your existing systems. We also welcome all good OEMs to discuss technology and developments with us.

OEM/ODM Process

TKT has a team of 135 engineers including design engineers, structural engineers, electrical engineers, test engineers, EMI/EMC engineers and after-sales engineers with complete design, development, testing and certification capabilities for refrigeration equipment and components. TKT BTMS is now available for electric Bus, truck, off-highway, boat and other commercial vehicles. We also provide design and technical support to the world's leading vehicle manufacturers.